CONTACT US

- Phone: +86-13665141391

- Email: info@formingchina.com

- Address: Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Close search

Door frame roll forming machine

door frame roll forming machine

1. Material texture: GI Yield Strength: 270-500Mpa2. Material thickness: 2mm3. feeding width: It depends on the profile you want to make, we will work out it4. Decoiler and loading capacity: 10T hydraulic decoiler, ( with brake equipment, inner diameter 508mm)5. Machine structure mode: Torii mode6.

1. Material texture: GI Yield Strength: 270-500Mpa

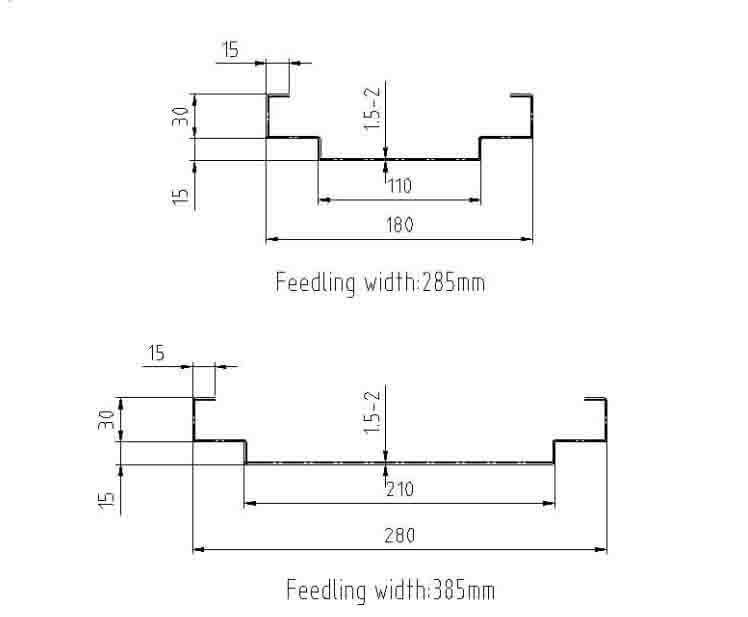

2. Material thickness: 2mm

3. feeding width: It depends on the profile you want to make, we will work out it

4. Decoiler and loading capacity: 10T hydraulic decoiler, ( with brake equipment, inner diameter 508mm)

5. Machine structure mode: Torii mode

6. Drive mode: gearbox drive

7. Main motor power: 15KW

8. Main reduction box: helical surface reduction box

9. Forming roller step: 18 steps

10. Roller material: Cr12MoV, vacuum hardening HRC 58-62°

11. Main shaft diameter: φ75mm

12. Cutting mode: Hydraulic cutting

13. Hydraulic station motor power:5KW

14. Servo feeding motor power: 2.2KW

15. PLC: Siemens PLC

16. Working speed: :6-12m/min

17. Voltage: Customized

B. Production technology process

Hydraulic decoiler →Leveling feeding →Servo feeding and punching →Guide feeding →Forming →hydraulic cutting→ Output

Company Address:

Company Address: Mobile: +86-13665141391

Mobile: +86-13665141391 Email:

info@formingchina.com

Email:

info@formingchina.comWe will contact you within 24 hours. ( WhatsApp/facebook:+86-13665141391)