CONTACT US

- Phone: +86-13665141391

- Email: info@formingchina.com

- Address: Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Close search

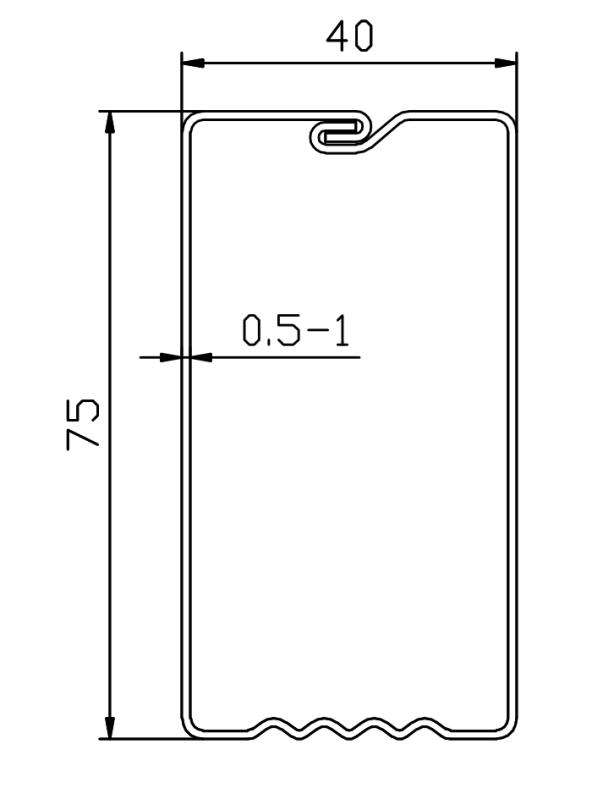

Square Tube And Round Tube And Pipe Roll Rorming Machine

square tube roll forming machine

1.Material Specification :0.48-1.0mm GI sheet,Strength yield≤550mpa2.De-coiler mode:3T manual de-coiler3.Main motor power:7.5KW4.Working speed:10-15mm/min5.Roller steps:16 horizontal rollers and a series of vertical rollers.6.Main shaft diameter:70mm7.Machine structure:Wallboard type

1.Material Specification :0.48-1.0mm GI sheet,Strength yield≤550mpa

2.De-coiler mode:3T manual de-coiler

3.Main motor power:7.5KW

4.Working speed:10-15mm/min

5.Roller steps:16 horizontal rollers and a series of vertical rollers.

6.Main shaft diameter:70mm

7.Machine structure:Wallboard type,single row 1.2 inches chain drive

8.Roller material:High quality GCR15 quenching treatment HRC 58-62. The rollers after quenching treatment and do the secondary processing, which can guarantee the roller accuracy and remove the rollers deformation after quenching treatment.

9. Control system:Panasonic PLC control system

10.Machine rack uses 450U-steel, location on two sides.

11.Cutting mode:flying saw following cutting mode after forming

B Production technology process

De-coiler ---- guide feeding ----- forming ----- Sizing(3 rollers + rotation)--- Die press out ----flying saw following cutting ---- output

Company Address:

Company Address: Mobile: +86-13665141391

Mobile: +86-13665141391 Email:

info@formingchina.com

Email:

info@formingchina.comWe will contact you within 24 hours. ( WhatsApp/facebook:+86-13665141391)